Description

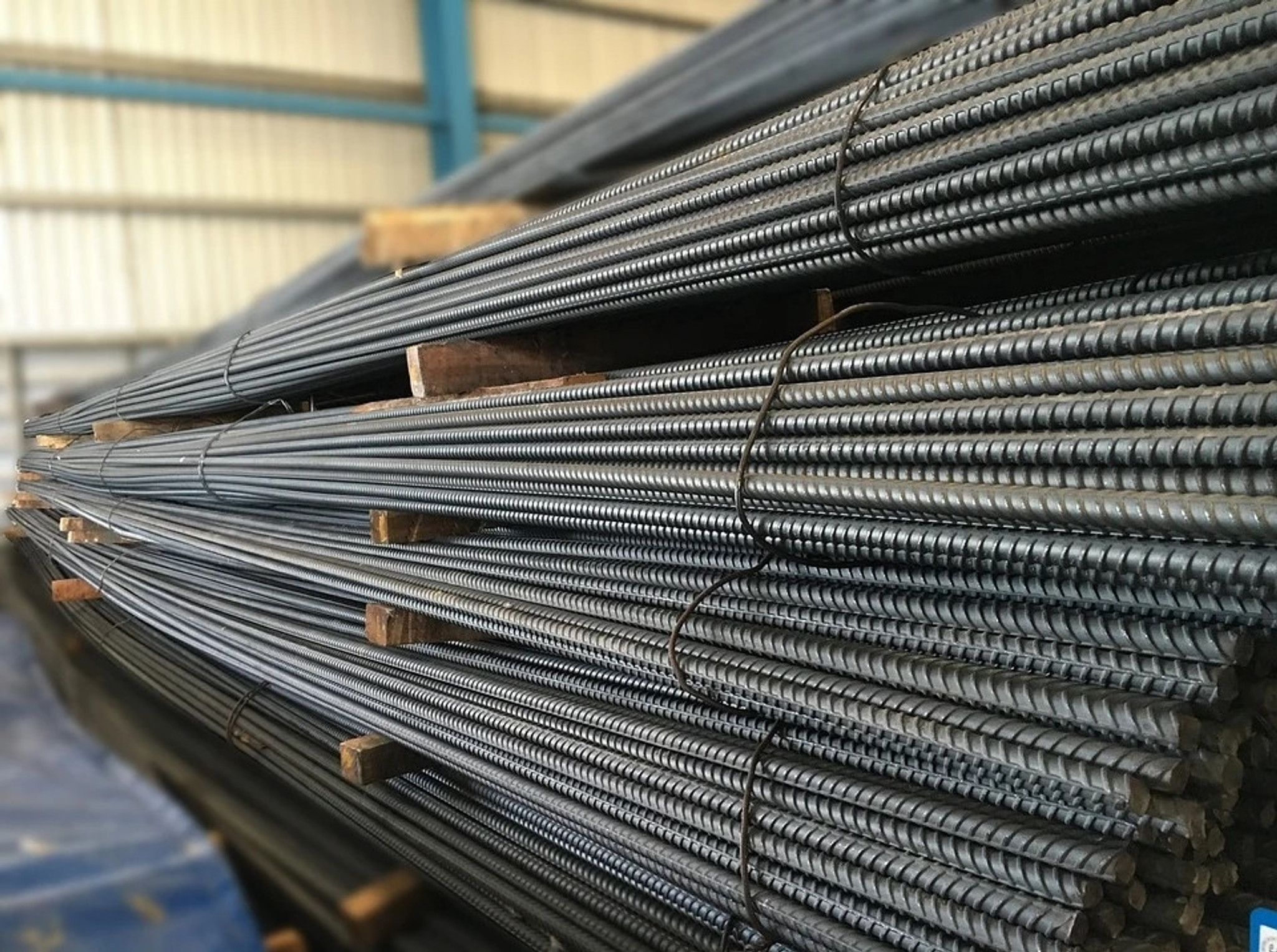

Rebar A2 (Semi-Rigid with Basic Ribbing) – Reinforcing Steel Supplier from Iran

Rebar A2, classified as Class S340, represents the second grade of reinforcing steel in the rebar classification system. Unlike smooth A1 rebars, A2 Rebar features a ribbed surface with a semi-rigid structure, offering an ideal balance between strength and ductility. This grade is designed to enhance bonding performance with concrete, providing improved structural stability compared to smooth rebars while maintaining sufficient flexibility for forming and bending operations.

With a yield strength of 340 MPa and a tensile strength of 500 MPa, A2 Rebar is widely used in general construction, residential buildings, and infrastructure projects where moderate load-bearing capacity and reliable reinforcement are required.

At Call2Supply, we proudly supply and export Rebar A2 from Iran, partnering with the country’s top steel producers, including Amir Kabir Khazar Steel, Khorasan Steel Complex, Esfahan Steel Company, Mianeh Steel, and Bafgh Yazd Steel.

Through our direct sourcing model and quality control process, we ensure every shipment meets international S340 standards, providing contractors and engineers worldwide with consistent and dependable rebar products.

Detailed Characteristics and Mechanical Advantages

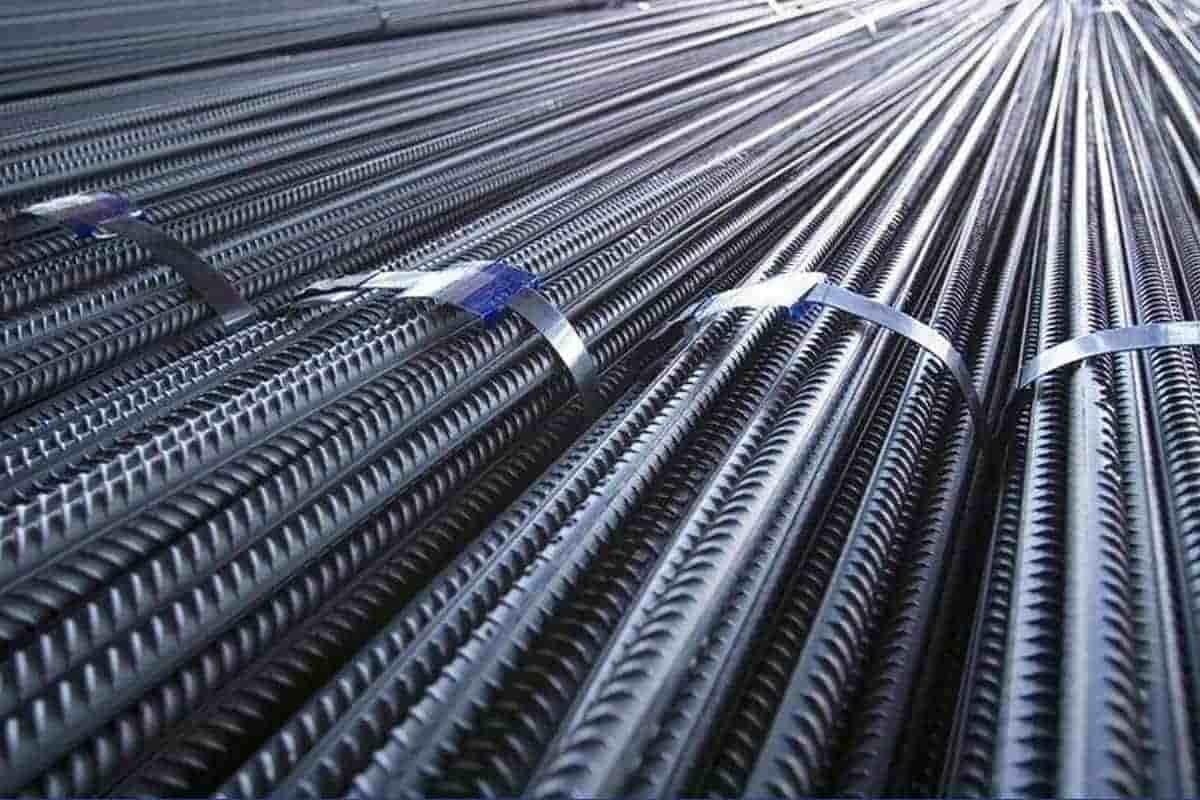

A2 Rebar is designed with a spiral rib pattern along the longitudinal axis, offering enhanced grip within concrete while retaining sufficient elasticity for structural flexibility.

This unique geometry ensures effective stress distribution between steel and concrete, reducing slippage and improving overall strength under dynamic loads.

Its semi-rigid mechanical profile allows it to endure demanding structural conditions without brittleness, making it a popular choice for medium-stress concrete applications such as columns, slabs, and beams.

In terms of composition, Rebar A2 has a slightly higher carbon content compared to A1, increasing strength but also reducing weldability. While welding is possible under controlled conditions, it’s generally recommended to avoid unnecessary welding unless absolutely essential, as high-carbon materials can be prone to cracking or distortion under thermal stress.

Key Characteristics and Benefits

-

Ribbed Semi-Rigid Design: The spiral ribs along the rebar surface create stronger adhesion to concrete, improving structural integrity.

-

Reliable Strength: Yield strength of 340 MPa and tensile strength of 500 MPa make A2 rebar suitable for standard to moderately heavy construction.

-

Enhanced Durability: Designed to resist cracking, slippage, and stress deformation, ensuring long-term reinforcement reliability.

-

Balanced Ductility: Semi-rigid structure provides both strength and manageable flexibility for forming and bending.

-

High-Quality Metallurgy: Produced under precise metallurgical control for uniform quality and predictable performance.

-

Welding Caution: Welding is technically possible but should only be performed under strict guidelines due to elevated carbon content.

-

Ideal Applications: Recommended for beams, slabs, foundations, and reinforced concrete frameworks in both residential and industrial projects.

Optimal Handling and Application Methods

Cutting and Bending:

Rebar A2 can be shaped using mechanical bending machines. Manual bending is possible but should be done carefully to avoid cracking in colder conditions.

Concrete Integration:

The ribbed spiral surface ensures effective mechanical bonding, providing superior anchorage strength and load distribution within concrete.

Welding Considerations:

Due to its higher carbon content, A2 Rebar should not be welded unless absolutely necessary. If welding is required, preheating and controlled cooling are essential to maintain structural integrity.

Storage and Maintenance:

Keep rebars in a dry, covered area to prevent oxidation or contamination before use.

Why Choose Call2Supply Is Smart Decision?

At Call2Supply, we provide comprehensive solutions for A2 Rebar supply and export, ensuring our clients receive the highest-quality materials and dependable global service.

-

Direct Sourcing from Leading Iranian Mills: We collaborate with Amir Kabir Khazar, Khorasan, Esfahan, Mianeh, and Bafgh Yazd Steel, ensuring authenticity and traceability.

-

Strict Quality Control: Every batch is tested to meet S340 mechanical standards before export.

-

Flexible Supply Contracts: Offering both short-term and long-term agreements suited to your project timeline.

-

Efficient Logistics: Fast and cost-effective delivery via Persian Gulf and Caspian Sea ports.

-

Competitive Pricing: Our optimized supply chain guarantees cost-effective pricing without sacrificing product quality.

-

Expert Support: Our engineering and export teams assist with technical data, documentation, and trade compliance.

-

Sustainable Operations: We partner with environmentally responsible steel manufacturers committed to reducing industrial emissions.

If you are looking for Rebar A2 from Iran, Call2supply company is ready to support you in your direct and swift supply in accordance with international trade. Contact our Team now or easily submit your order online.

Mehmet –

Thank you for your good service. Iranian rebar is of good quality.