Description

Magnesite (MgCO₃), carbonate magnesite, is a natural mineral primarily composed of magnesium carbonate. It is a critical raw material for the steel, refractory, chemical, and agriculture sectors due to its high magnesium content and thermal resistance. Magnesite is used in the production of magnesia (MgO), refractory bricks, fertilizers, and magnesium compounds, making it an essential mineral in global trade.

At Call2Supply, we provide Iranian-origin magnesite in different grades and forms, including raw magnesite lumps, magnesite powder, and calcined magnesite, tailored to meet buyer requirements in international markets

-

Applications of Magnesite

- Steel Industry: Refractory linings in furnaces, converters, and ladles

- Chemical Industry: Production of magnesium oxide, fertilizers, and flame retardants

- Construction: Flooring, panels, and magnesia boards

- Agriculture: Magnesium supplement for soil and animal feed

- Environmental Uses: Neutralization of acidic wastewater, flue gas treatment

-

Packaging & Delivery

*Bulk shipments in vessels (handymax, supramax, panamax)

* Jumbo bags (1–1.5 MT) or 25–50 kg PP bags for powders

* Flexible delivery terms: FOB Iran ports, CFR, CIF

-

Types of Magnesite We Supply

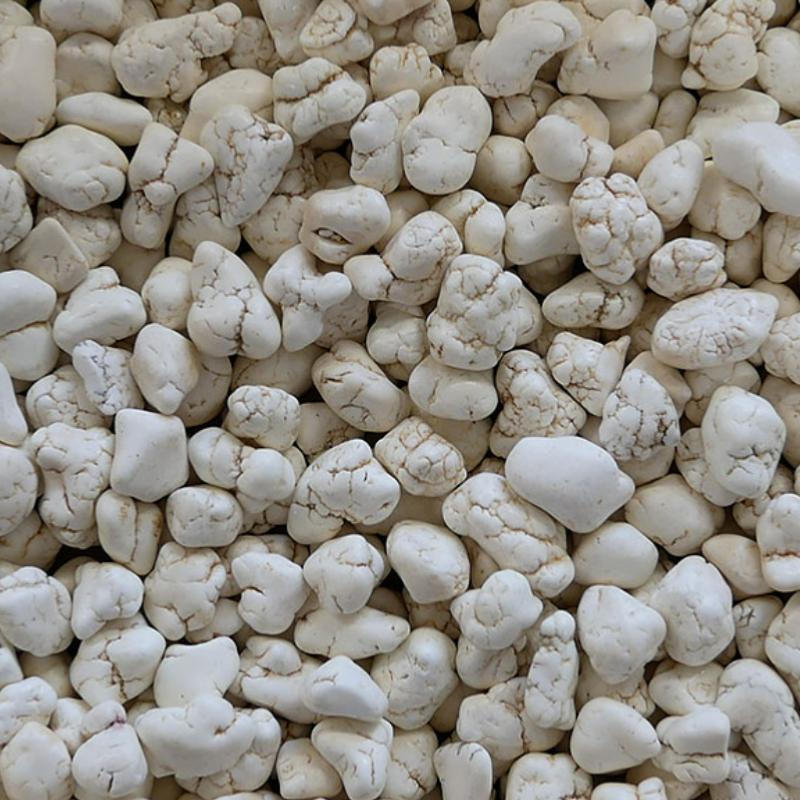

1. Raw Magnesite (Carbonate Magnesite Lumps)

Naturally mined magnesite available in lump form.

Applications Refractory production, magnesium oxide (MgO) manufacturing, steelmaking, and agriculture.

Specifications(typical range, customizable):

MgCO₃: 85% – 95%

SiO₂: < 2% – 5%

Fe₂O₃: < 1%

Size: 10–150 mm (screened lumps)

2. Magnesite Powder

Ground and processed magnesite in fine powder form.

Applications: Fertilizers, flame retardants, plastics, ceramics, animal feed additives.

Specifications(typical range):

MgCO₃: 85% – 95%

Particle size: 200–400 mesh (customized)

Moisture: < 1%

3. Calcined Magnesite (Caustic Calcined Magnesia – CCM)

Produced by calcining magnesite at controlled temperatures to obtain MgO.

Applications: Refractory linings, foundries, welding electrodes, water treatment, and chemicals.

Advantages: High reactivity, thermal stability, versatile industrial applications.

Specifications(typical range):

MgO: 85% – 92%

LOI (Loss on Ignition): < 6%

Size: Powder (100–325 mesh) or granules

4. Dead Burned Magnesite (DBM)

High-temperature calcined magnesite with low reactivity and high density.

Applications: Refractory bricks, steelmaking furnaces, cement and glass industries.

Specifications(typical range):

MgO: 88% – 96%

Bulk density: > 3.2 g/cm³

Size: 0–50 mm

Why Choose Call2Supply for Magnesite?

Direct sourcing: from Iranian magnesite deposits

Wide product range: raw, calcined, and DBM magnesite

Customized grades & sizing: for steel, refractory, chemical, and agriculture industries

Flexible logistics: via Bandar Abbas, Chabahar, and Persian Gulf ports

Competitive pricing & consistent quality: with long-term supply capacity

Get a Quote

Looking for a reliable supplier of magnesite (MgCO₃) from Iran?

Contact Call2Supply today for customized offers on raw magnesite, magnesite powder, calcined magnesia (CCM), and dead burned magnesite (DBM). We ensure consistent quality, reliable supply chain, and competitive export pricing.

Reviews

There are no reviews yet.