Introduction to Iranian Kaolin

Iranian kaolin is widely recognized as one of the most reliable and high-quality industrial minerals available on the global market today. Its reputation is built on a combination of naturally favorable geological formation, meticulous extraction methods, and well-established processing practices. Kaolin produced in Iran is particularly valued for its natural purity, fine particle structure, high brightness, and chemical and thermal stability. These characteristics make Iranian kaolin an ideal raw material for a wide range of manufacturing industries that prioritize consistency, performance, and efficiency in their production processes.

In recent years, there has been a significant rise in international interest toward Iranian kaolin. Global industries increasingly seek dependable sources of industrial minerals that can deliver both high quality and cost-effectiveness. Iran’s kaolin mining sector, supported by modern extraction techniques and advanced processing facilities, has successfully positioned itself as a consistent and trustworthy supplier. Additionally, the country benefits from strategic access to regional and international shipping routes, which facilitates smooth export operations and timely delivery to industrial markets worldwide.

This article, presented by Call2Supply, offers a detailed overview of Iranian kaolin, highlighting its industrial applications, performance advantages, and critical role in international supply chains. Emphasis is placed on the quality stability, controlled production processes, and long-term suitability for export markets, drawing on Call2Supply’s direct sourcing from its own kaolin mines. By maintaining full control over extraction and processing, the company ensures that each batch meets international quality standards, enabling manufacturers to rely on consistent material for their operations.

Quality Characteristics and Processing Approach

The performance of kaolin in industrial applications is highly dependent on both its physical and chemical properties. Iranian kaolin possesses a naturally favorable balance of alumina and silica, along with very low levels of undesirable impurities. This composition provides a foundation for high-performance behavior across diverse industrial processes. Moreover, Iranian kaolin exhibits naturally high brightness, which is essential for applications where visual quality is critical.

To ensure that these valuable properties are preserved and optimized, kaolin undergoes a carefully managed and multi-stage processing procedure. The initial stages typically include crushing, which reduces large ore chunks into smaller particles suitable for further handling. Following this, washing and purification remove residual dirt, iron oxides, and other unwanted materials. In some cases, magnetic separation is employed to eliminate traces of iron, further enhancing purity and brightness. The material then undergoes particle size classification, allowing manufacturers to select specific grades tailored to different industrial requirements. Depending on the intended application, kaolin may also be dried or micronized, producing ultra-fine powders suitable for high-end industrial uses.

Quality control is central throughout the entire production process. Continuous testing of chemical composition, particle size distribution, brightness, moisture content, and impurity levels ensures that every batch meets defined specifications. This rigorous approach guarantees consistent performance and reliability over time, which is particularly important for international markets where uniformity is non-negotiable. By maintaining such standards, suppliers can confidently provide kaolin that integrates seamlessly into diverse industrial processes without requiring extensive adjustments or additional processing.

Industrial Applications of Iranian Kaolin

One of the key strengths of Iranian kaolin lies in its versatility. The combination of its fine physical structure, chemical stability, and controlled particle size makes it suitable for a broad range of industrial applications. Its use spans from traditional manufacturing to highly specialized sectors where performance and reliability are critical.

Ceramics and Tile Manufacturing

In the ceramics and tile industry, kaolin is an essential component that influences forming, firing, and the final appearance of products. Iranian kaolin enhances plasticity during shaping, enabling better molding and forming of ceramic bodies. It also improves dimensional stability during firing, reducing the risk of warping or cracking in tiles, porcelain, and sanitaryware. High brightness and color consistency further contribute to superior visual quality, making it highly suitable for wall and floor tiles, porcelain products, tableware, and sanitary ceramics. These characteristics ensure that manufacturers can produce high-quality, visually appealing, and mechanically reliable products that meet market expectations.

Paper and Packaging Applications

In the paper and packaging industry, kaolin is primarily used as a filler and coating material. Its incorporation improves surface smoothness, brightness, and opacity, which are critical for high-quality printability and visual appearance. Controlled particle size distribution ensures better ink absorption and uniform coating, resulting in sharper prints and more consistent color reproduction. Additionally, Iranian kaolin contributes to efficient material usage, reducing the need for more expensive additives while maintaining high performance. This balance of quality and cost-effectiveness has made Iranian kaolin a preferred choice for paper mills and packaging manufacturers aiming to optimize both product quality and production economics.

Paints and Coatings

In paints and coatings, kaolin serves as a performance-enhancing filler, rather than merely an extender. Iranian kaolin improves opacity, rheological control, and resistance to chemical and mechanical stress. Its stable particle structure ensures uniform dispersion in formulations, leading to coatings with consistent color, smooth texture, and enhanced durability. These properties are particularly valuable in both decorative and industrial paints, where long-lasting performance and visual quality are essential. The reliability of Iranian kaolin allows manufacturers to maintain consistent product specifications while minimizing the risk of formulation issues during production.

Plastics and Rubber Compounds

Kaolin is widely incorporated into plastics and rubber compounds to enhance mechanical properties while maintaining processability. Iranian kaolin improves strength, surface finish, and dimensional stability, making it suitable for a wide range of products, including PVC profiles, hoses, cables, molded components, and rubber goods. Its use also helps manufacturers optimize production costs by reducing the reliance on more expensive raw materials without compromising functionality. The fine particle structure and chemical inertness of Iranian kaolin ensure that it integrates well into complex formulations, supporting consistent product performance across batches.

Refractory and High-Temperature Applications

In refractory applications, material stability under high temperature is paramount. High-purity Iranian kaolin is used in refractory bricks, kiln linings, and furnace components due to its excellent resistance to thermal shock and structural degradation. These properties extend service life, reduce maintenance frequency, and improve operational efficiency in high-temperature industrial processes. Consistency in thermal behavior ensures predictable performance even under extreme conditions, which is critical for industries relying on continuous high-temperature operations.

Construction and Building Materials

Kaolin is also valuable in construction applications, including cement, concrete, lightweight panels, and ceramic building materials. Its incorporation improves workability, surface finish, and sometimes thermal performance, enhancing both production efficiency and the durability of finished products. By providing consistent quality, Iranian kaolin allows construction material manufacturers to achieve predictable results, reduce production variability, and maintain high standards in end-use applications.

Pharmaceutical and Cosmetic Uses

The softness, chemical inertness, and high purity of Iranian kaolin make it suitable for sensitive applications in pharmaceuticals and cosmetics. In pharmaceuticals, kaolin acts as an absorbent and protective agent, while in cosmetics, it is used as a base for powders, masks, and skincare formulations. In these applications, safety, purity, and consistency are critical. Iranian kaolin, produced under rigorous quality control standards, meets these requirements, ensuring reliable performance without compromising product safety.

Advantages of Iranian Kaolin in International Supply

Iranian kaolin possesses a combination of characteristics that make it particularly attractive to international buyers:

- Naturally high purity with minimal impurity content, ensuring consistent quality

- Bright and uniform color, suitable for visual and decorative applications

- Thermal and chemical stability, enabling reliable performance across industrial processes

- Versatility across industries, including ceramics, paper, coatings, plastics, rubber, construction, and pharmaceuticals

- Cost-effectiveness, supported by efficient extraction, processing, and local resource availability

- Reliable availability, ensuring continuous supply to meet long-term production needs

These advantages enable Iranian kaolin to integrate seamlessly into existing manufacturing systems without extensive reformulation or additional processing. Its consistency supports operational stability, reduces waste, and enhances the overall efficiency of industrial processes, making it a preferred choice for manufacturers seeking high-quality, reliable raw materials.

Export Orientation and Key Markets

Iran’s kaolin industry benefits from well-developed logistics infrastructure and strategic proximity to major regional markets. This positioning facilitates efficient international distribution, enabling suppliers to meet diverse customer requirements across multiple sectors. Demand is particularly strong from industries seeking dependable industrial minerals for ceramics, paper, construction, and various manufacturing applications.

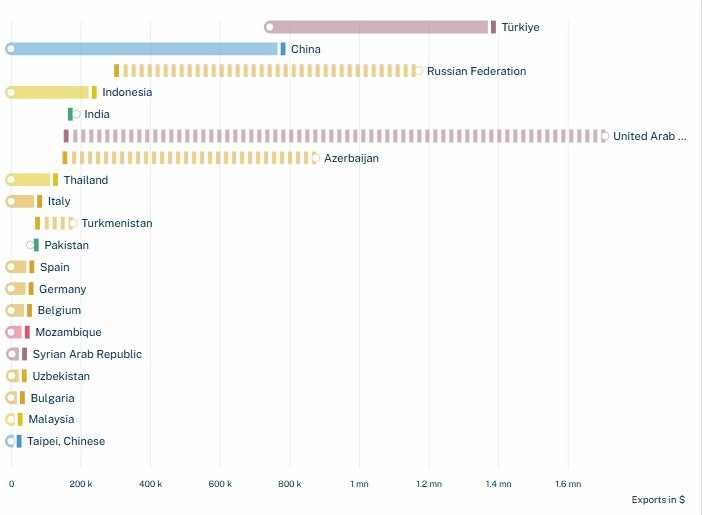

Based on export potential data, the key markets for Iranian kaolin include Turkey, Iraq, Russia, India, China, and the United Arab Emirates, where the mineral is utilized across a wide range of industrial processes. These markets value stable supply, predictable quality, and consistent performance, all of which Iranian kaolin reliably delivers. By maintaining strict quality control and production oversight, suppliers ensure that international clients receive a product that meets global standards, supporting uninterrupted operations and long-term industrial partnerships.

Packaging, Logistics, and Supply Continuity

Iranian kaolin is supplied in multiple packaging formats to suit different handling, storage, and transportation needs. These include bulk shipments, jumbo bags, and standard 25 kg or 50 kg bags, along with specially graded and micronized products for high-precision applications. Such flexibility allows manufacturers to select the appropriate product form for their production processes, optimizing handling efficiency and reducing potential material loss.

Access to regional ports and well-established shipping networks ensures timely delivery and logistical flexibility, allowing suppliers to adapt quickly to changing production schedules and customer demands. This reliability in transportation and supply continuity is a key factor for international buyers, particularly those operating in time-sensitive manufacturing sectors.

Conclusion

Iranian kaolin represents a dependable, high-performing industrial mineral with wide applicability across modern manufacturing industries. Its natural purity, structural consistency, and stability under both thermal and chemical conditions make it suitable for applications in ceramics, paper, coatings, plastics, rubber, refractories, construction materials, and selected pharmaceutical and cosmetic products.

By sourcing kaolin directly from its own mines, Call2Supply ensures close control over extraction, processing, and quality assurance, providing a consistent, high-quality product for international markets. This approach emphasizes long-term reliability rather than short-term promotion, supporting sustainable cooperation with global industrial partners. Through a focus on quality, stability, and operational efficiency, Iranian kaolin continues to serve as a trusted raw material for manufacturers seeking performance, consistency, and cost-effectiveness in their production processes.